Clinical Resource: A comparison of performance characteristics of a new High Performance Dressing compared with a 100% CMC fibre based dressing and its reinforced equivalent

C. Walsh, C. Bradford, S. Krajnakova, M. Knight

Advanced Medical Solutions Ltd. UK

Clinical Resource

A comparison of performance characteristics of a new High Performance Dressing, Aquafiber Extra, compared with a 100% CMC fibre based dressing and its reinforced equivalent

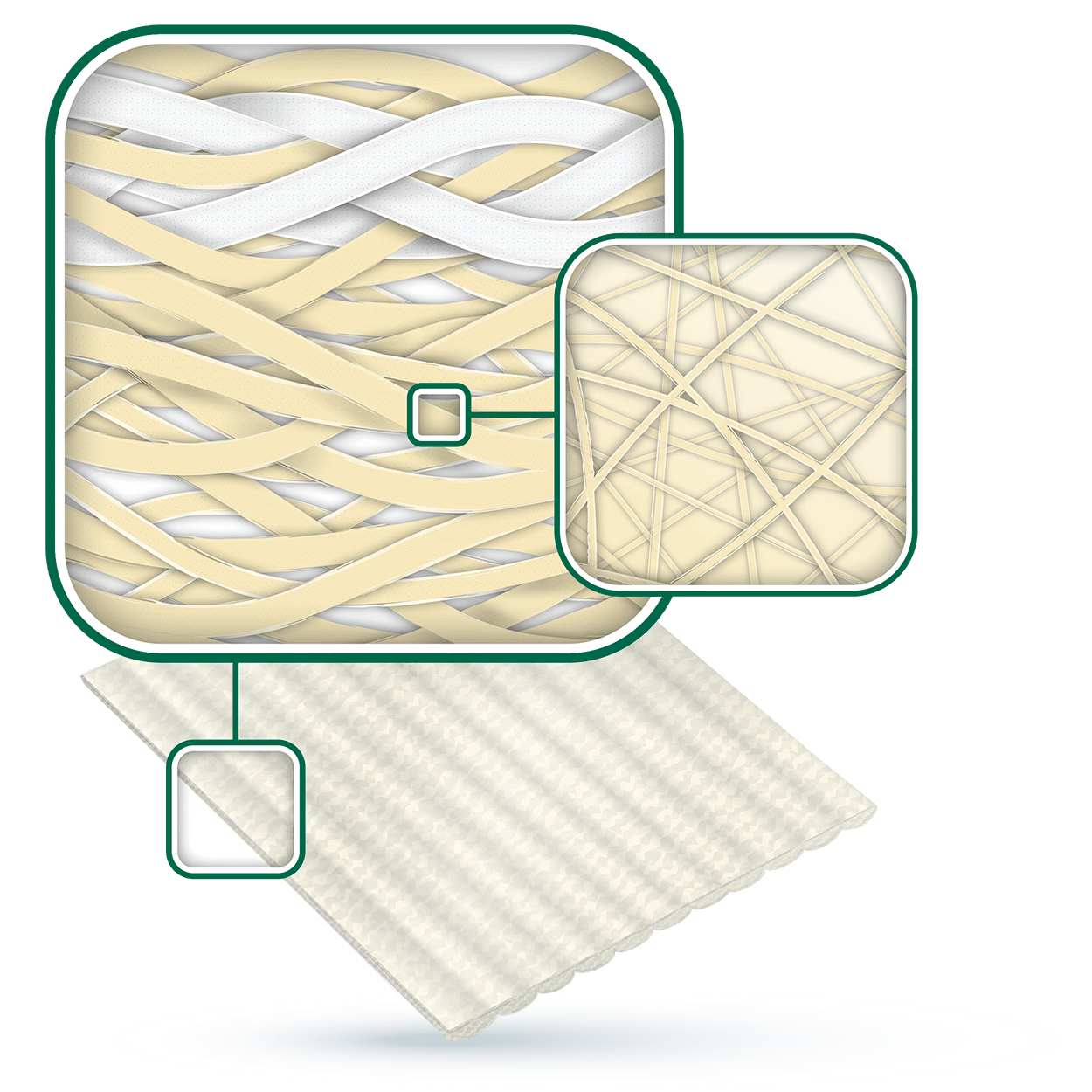

BACKGROUND

HPD Key characteristics:

- High gelling

- High absorbency

- Good wet and dry strength

- Low lateral wicking

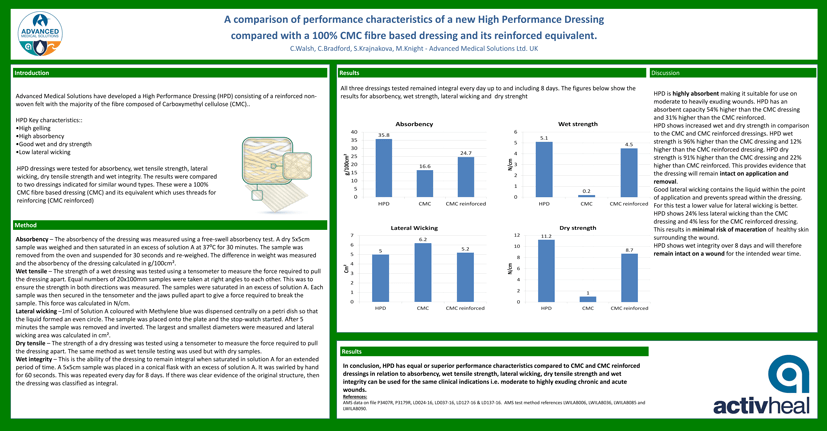

High Performance Dressings were tested for absorbency, wet tensile strength, lateral wicking, dry tensile strength and wet integrity. The results were compared to two dressings indicated for similar wound types. These were a 100% CMC fibre based dressing (CMC) and its equivalent which uses threads for reinforcing (CMC reinforced).

METHOD

Wet tensile – The strength of a wet dressing was tested using a tensometer to measure the force required to pull the dressing apart. Equal numbers of 20x100mm samples were taken at right angles to each other. This was to ensure the strength in both directions was measured. The samples were saturated in an excess of solution A. Each sample was then secured in the tensometer and the jaws pulled apart to give a force required to break the sample. This force was calculated in N/cm.

Lateral wicking –1ml of Solution A coloured with Methylene blue was dispensed centrally on a petri dish so that the liquid formed an even circle. The sample was placed onto the plate and the stop-watch started. After 5 minutes the sample was removed and inverted. The largest and smallest diameters were measured and lateral wicking area was calculated in cm².

Dry tensile – The strength of a dry dressing was tested using a tensometer to measure the force required to pull the dressing apart. The same method as wet tensile testing was used but with dry samples.

Wet integrity – This is the ability of the dressing to remain integral when saturated in solution A for an extended period of time. A 5x5cm sample was placed in a conical flask with an excess of solution A. It was swirled by hand for 60 seconds. This was repeated every day for 8 days. If there was clear evidence of the original structure, then the dressing was classified as integral.

RESULTS

Absorbency (g/100cm2)

Lateral Wicking (cm2)

Wet Strength (N/cm)

Dry Strength (N/cm)

DISCUSSION

Good lateral wicking contains the liquid within the point of application and prevents spread within the dressing. For this test a lower value for lateral wicking is better. High Performance Dressing shows 24% less lateral wicking than the CMC dressing and 4% less for the CMC reinforced dressing. This results in minimal risk of maceration of healthy skin surrounding the wound. HPD shows wet integrity over 8 days and will therefore remain intact on a wound for the intended wear time.

CONCLUSION

References

AMS data on file P3407R, P3179R, LD024-16, LD037-16, LD127-16 & LD137-16.

AMS test method references LWILAB006, LWILAB036, LWILAB085 and LWILAB090.

CONTACT US FOR MORE INFORMATION

Discover ActivHeal®

Social Media

Our Product Range

AMS Group

ActivHeal®, its logo and the Advanced Medical Solutions logos are registered trademarks of Advanced Medical Solutions Ltd.

Copyright © Advanced Medical Solutions Limited | Design by Lumisi Ltd